Client: Professional Sports Facility Developer, Africa

Solution: Custom-designed indoor climbing walls

Key Highlights:

✅ 100% modular manufacturing

✅ Zero on-site engineering deployment

✅ Remote installation support

✅ 3D design-to-installation precision

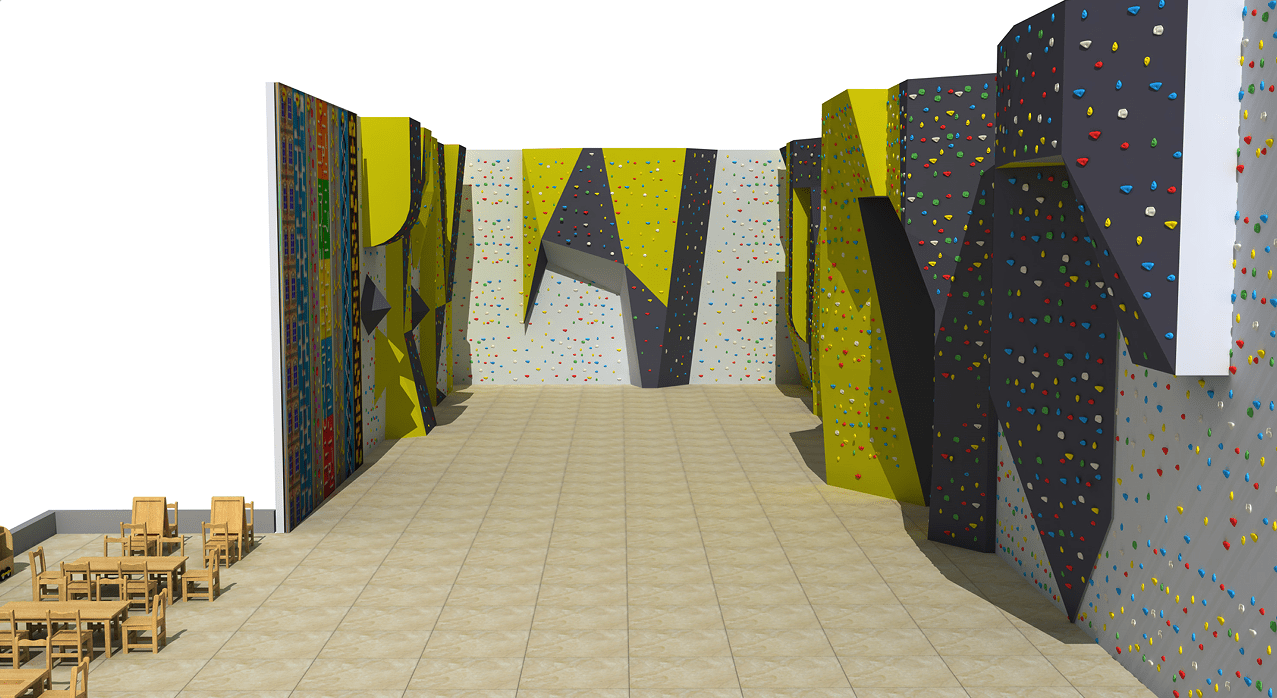

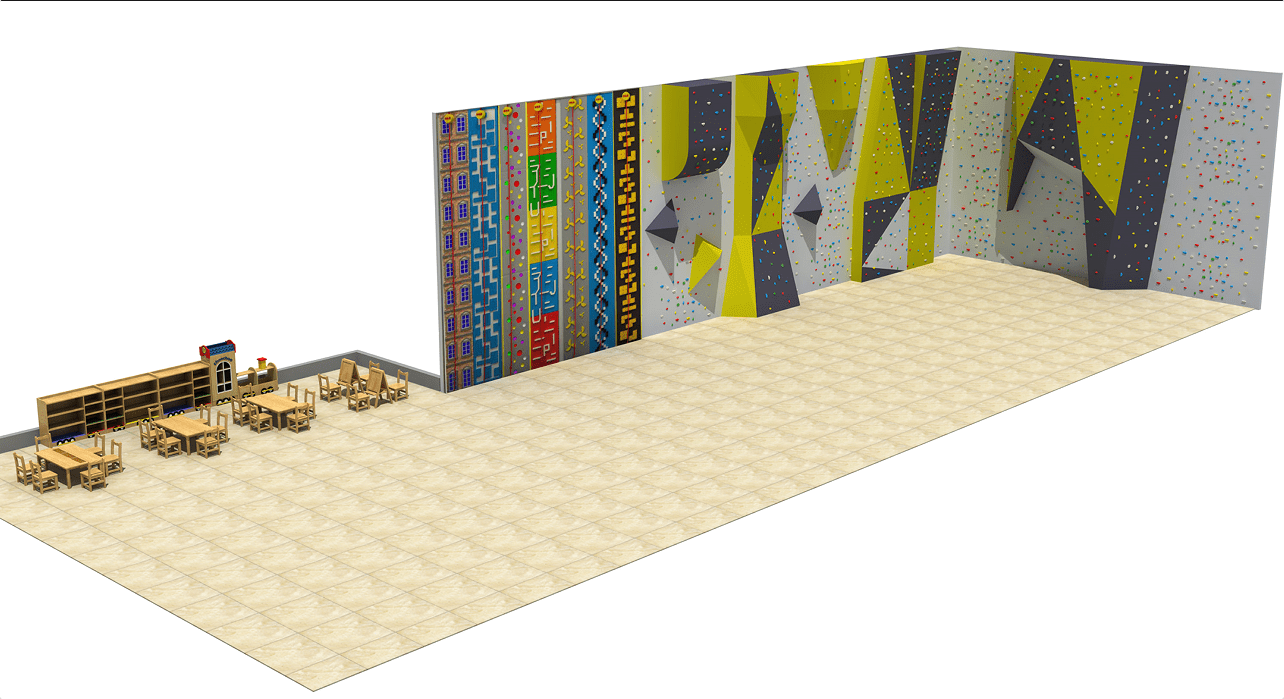

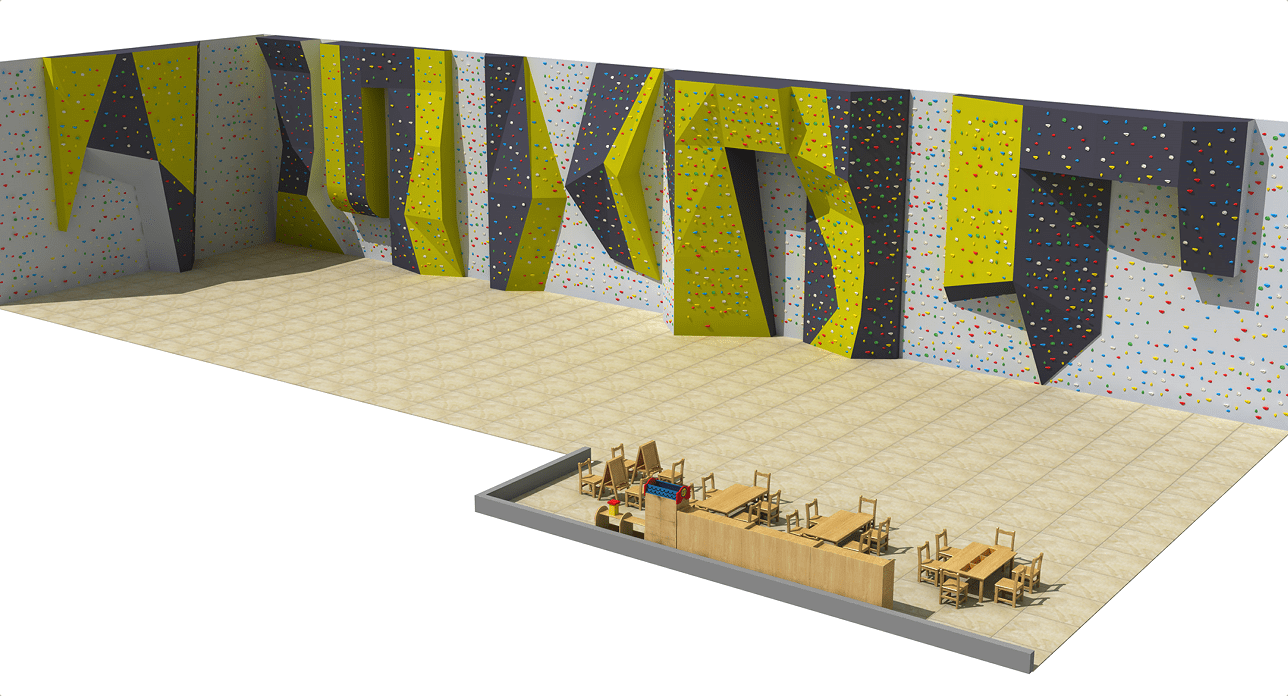

Phase 1: Collaborative Design Confirmation

Our partnership began with interactive virtual planning:

- Space Optimization: Designed multi-level climbing zones for indoor facilities

- Theme Execution: Vibrant purple-yellow color scheme with ergonomic routes

- Safety Integration: Strategically angled panels with fall-zone planning

Your Advantage: Real-time revisions ensured design alignment before cutting materials.

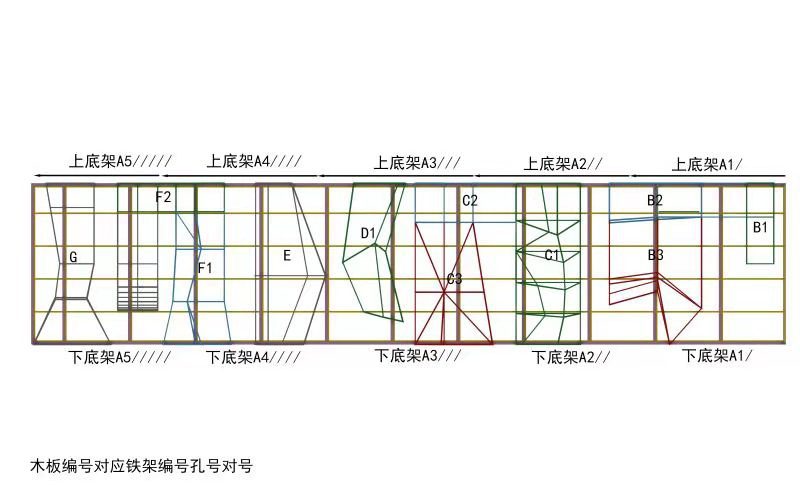

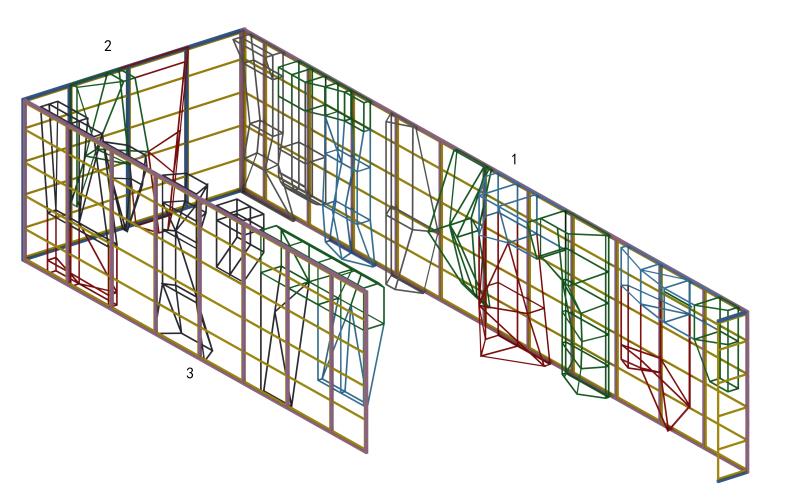

Phase 2: Precision Modular Manufacturing

[Production & Pre-Assembly]

Engineering breakthrough:

- Color-Coded Zoning : Pre-labeled segments for foolproof assembly

- Workshop Pre-Fabrication :

• CNC-cut foam-backed panels (white/black frames)

• Shock-absorbent structural skeletons

• Pre-installed anchor points - Ready-to-Ship Packaging :

• Impact-resistant plastic wrapping

• Flat-pack optimized containers

Why it mattered: Factory-finished modules eliminated 83% of on-site labor.

Phase 3: Client-Led Installation with Remote Guidance

[ Installation Site]

Self-installation success drivers:

- Diagram-Driven Assembly :

- Provided CAD schematics with torque specifications

- Color-matched component placement guides

- Real-Time Troubleshooting :

- 24/7 video support via WhatsApp

- Digital markup tools (red circles/arrows)

- Structural Confidence:

- Bolt-on panel connections (no welding)

- Pre-tested load-bearing capacity

Client Testimonial Implied: “Your engineers never left their China office – we never needed them to!”

Technical Specifications

| Feature | Innovation | Client Benefit |

|---|---|---|

| Modular Panel System | Interlocking steel-framed units | 60% faster install |

| EPDM Foam Surfaces | UV-stable, sweat-resistant | 8-year durability |

| Angled Climbing Zones | 25°-45° difficulty gradients | Skill progression |

| Remote Support | Shared-AR annotation tools | Zero construction delays |

Why Global Clients Choose This Model

- 💰 60% Cost Reduction vs. traditional on-site construction

- 🌍 Logistics Efficiency: 40% container space savings

- 🛠️ Empowerment Culture: Technical clients retain full control

- 📊 Predictable Timelines: Manufacturing/assembly decoupling

Project Outcome

- Timeline: Design-to-commissioning in 11 weeks

- Safety Certification: Passed EN 12572-1:2017 testing

- Client ROI: Revenue generation began 3 weeks post-installation

Invitation to Innovate

Transform your sports facility with our modular design + remote support formula:

- 🚀 Free 3D conceptualization within 72 hours

- 📦 Transparent modular pricing breakdowns

- 🌐 Bilingual installation portals (English/French)